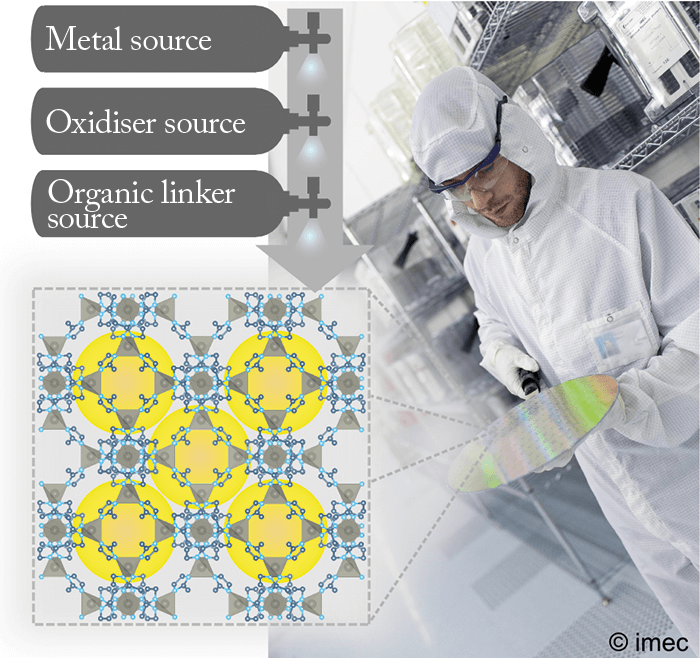

MOFs are porous crystalline materials composed of metal ions and organic molecules. They have excited researchers because of their extremely large surface-areas – the largest of any known material – and the flexibility with which their chemical functionality can be tuned. They are also very robust, with high mechanical and thermal stabilities. However, the current synthesis pathways used to obtain MOFs are incompatible with nanofabrication, meaning they cannot be designed and manufactured at the nanoscale. Researchers from the Center for Surface Chemistry and Catalysis at the University of Leuven set out to develop a method of synthesizing MOFs that aligns with the way nanoscale devices are manufactured (1). “Vapor phase deposition methods are the cornerstone of nanofabrication,” says Rob Ameloot, lead author of the study. “We therefore set out to synthesize a crystalline and porous MOF using vaporized precursors.”

The researchers were able to synthesize the MOFs in a two-step process. “In the first step we rely on an established technology: atomic layer deposition of metal oxides,” says Ameloot. “In the second step, we react these sacrificial metal oxide films with a vaporized MOF ligand,” he says. “The trick is to get the conditions at the solid-vapor interface just right to enable the formation of a porous and crystalline material, a feat that thus far required the presence of a solvent.”

Through the development of a synthesis method compatible with nanofabrication, the researchers have opened the door to a wide range of industrial applications – including some within analytical science. “We are very enthusiastic about applying MOFs to gas sensors, and we’re working on it as we speak,” says Ameloot. “The perfectly uniform nanometer-sized pockets in the MOF materials are ideal to capture small molecules; important examples include carbon dioxide, for integration in smart AC, and volatile organic compounds (VOCs) such as formaldehyde, acetone, benzene, and so on,” he adds. “The latter group of compounds are a major part of indoor and industrial air pollution, and it is becoming increasingly interesting to detect changes in the concentration of these marker molecules in breath, for early diagnosis of diseases such as cancer.”

Ameloot and his colleagues believe that MOF-based sensors could have a major impact on small molecule detection and monitoring, especially for applications that need sub-ppm level sensitivity.

References

- I Stassen et al., “Chemical vapour deposition of zeolitic imidazolate framework thin films”, Nature Materials [EPUB ahead of print] (2015).